For more products please visit http://www.weedo.ltd / https://www.weedo3d.com

User Tools

Sidebar

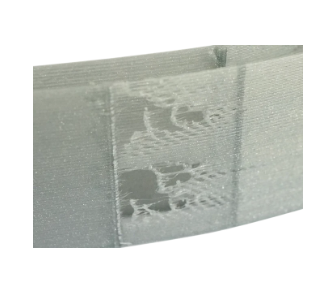

Inconsistent extrusion & How to fix ender extrusion.

Possible Reasons

1. The consumables are stuttered into the wire, and the rotation of the consumables is not smooth. Adjust the position of the rack so that the feed wire is in the smoothest direction.

2.. The wire diameter of the filaments will be larger and smaller. Please use high-quality filaments.

3. Run Catton in the Z direction. After shutting down, manually let the Nozzle assembly run up and down, found that the operation is very blocking, apply lubricating silicone grease on the edge of the pulley to make it run smoothly.

4. Check the print speed and print temperature. If the printing speed is too fast, the printing temperature is too low, and the silk production speed can not keep up with the running speed, it will cause this problem.

5. The nozzle is clogged and contains impurities, and the printing is not smooth. Verify that the problem still exists after replacing the sprinkler.